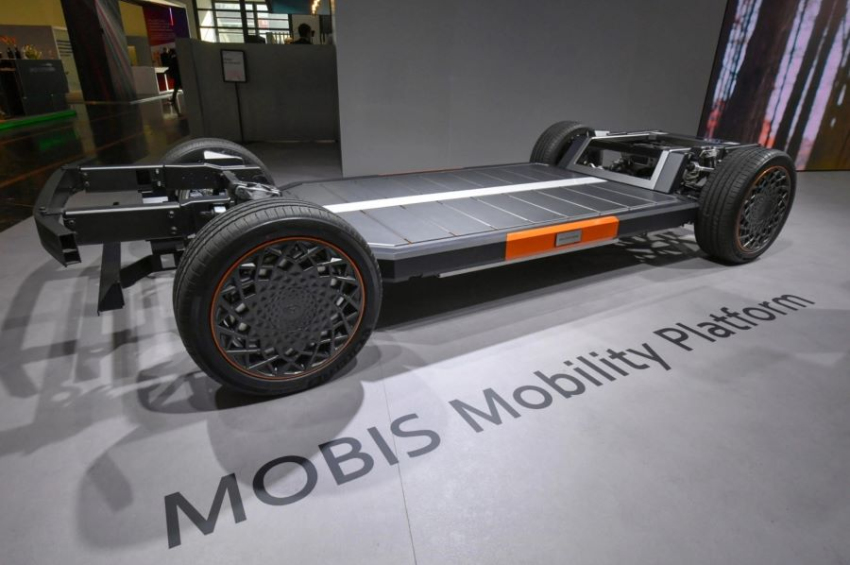

Hyundai Mobis unveils breakthrough fire extinguishing system integrated into EV batteries

As the electric vehicle (EV) industry accelerates globally, Hyundai Mobis — a key affiliate of Hyundai Motor Group — has unveiled a groundbreaking safety innovation: a battery-integrated fire extinguishing system, which is designed to detect and neutralize fire risks in EVs before they escalate.

This next-generation system marks a major advancement in EV battery safety. Equipped with real-time sensors that monitor temperature, voltage, and internal pressure, the technology is capable of detecting early warning signs of battery malfunction, the company said on its website.

More to read:

Hyundai unveils revolutionary pulsating battery technology

In critical situations, it autonomously deploys a powerful extinguishing agent, directly targeting the affected area to prevent or delay thermal runaway, the rapid and dangerous spread of heat within battery cells.

The extinguishing material used is five times more potent than a standard 3.3kg home fire extinguisher and is praised for its high permeability, insulation capacity, and cooling efficiency—all while being environmentally friendly and safe for human use.

Hyundai Mobis has applied for three domestic and international patents covering key elements of the system, including the battery cover design, the fire extinguishing mechanism, a high-pressure spraying system, and specialized delivery pipes.

The system operates through a combination of advanced sensors and decision-making software. If abnormal data is detected — such as an unusual rise in pressure or temperature — the software rapidly triggers the extinguishing system with precision targeting to the risk zone (pictured above). The control logic is built with multiple redundancies and robust algorithms to ensure fail-safe performance even in complex scenarios.

With major regions such as Europe, China, and India now mandating that EVs delay thermal runaway by at least five minutes after cell failure, Hyundai Mobis’ solution is well-timed. Its Battery System Assembly (BSA) not only meets but aims to exceed these safety thresholds.

More to read:

What is regenerative battery and why it’s better than lithium-ion ones

The BSA includes an integrated Battery Management System (BMS), fire suppression device, a heat-resistant battery case, and proprietary software that oversees and coordinates all components.

Initially, Hyundai Mobis is aiming to commercialize the new fire-extinguishing system within the commercial vehicle sector, where thermal safety is a top priority due to larger battery sizes and longer operational hours.

To further enhance safety, Hyundai Mobis has also developed a pulsating heat pipe, a new thermal management component placed between battery cells. This innovation actively dissipates heat to prevent localized overheating and improves the overall thermal stability of the battery pack.